Description

Polyester resins are the most common resin systems used in the manufacture of FRP (Fiber Reinforced Plastics). Because it is low cost and their processed physical properties meet many needs in the commercial composite industry.

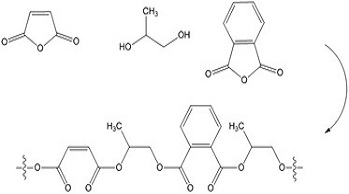

Types of unsaturated polyester resin (UP

.jpg)

Phthalic anhydride based resins: These resins are sometimes called general purpose or GP resins. They are usually inexpensive polyester resins and are used in places where high mechanical properties and corrosion resistance and high temperatures are not required. These resins can be formulated with a styrene percentage of about 33% to 38%.

Isophthalic acid-based resins: These resins have higher mechanical properties and corrosion resistance than ortho resins. Due to the high molecular weight of isophthalic-based polymers, more monostyrene is required to be added to the resin to have a suitable viscosity to work. reach ISO resins usually have a styrene percentage of about 42% to 50%.

Dicyclopentadiene-based resins: These resins are used where decorative finishes are more sensitive. These resins have less volume shrinkage during processing and create the least surface protrusions. These resins are almost similar to ortho resins in terms of physical properties and the percentage of capture They are usually around 35% to 38%.

Terephthalic based resins: Unsaturated polyester resin with very high reactivity and medium viscosity, its mechanical properties are between orthophthalic and isophthalic resins and are used in sculpture, stone cutting and marine industries. This type of resin is the most widely used resin and it dissolves in styrene.

Property

• Heat resistance, dimensional stability against temperature changes

• High tensile and compressive strength

• High bending strength

• Resistance to corrosion and chemical agents

• Excellent dielectric properties

• Good fluidity when heated

• abrasion resistance

• Good mechanical resistance

Application

Unsaturated polyester resins are mainly used in the production of fiber-reinforced plastics and plastic products, including sanitary ware, tanks, pipes, mesh and high-performance components for the marine and shipping industries, such as closures and hull panels. Fenders, boat hooks are used.

• GRP-FRP pipes

• Floating

• Furniture making

• Air and space industry

• military industries

• Sports industries

• Decorative pieces and sculptures

• Natural and artificial stones

At first, polyester resin is in the form of a thick liquid and when it is mixed with accelerator and catalyst or hardener, after some time its temperature rises and it becomes a jelly and then it becomes hard and solid.

Maintenance

Polyester resin should be kept in a cool and dark place (below 25 degrees Celsius). The life of the resin, if it is of good quality, reaches twelve months. By increasing and decreasing the hardener, the hardening time can be adjusted.

safety

Due to strong and destructive reactions, never directly combine acid with cobalt to prepare the resin. Cobalt should be used first and then acid. The above resin is completely flammable, it is recommended to wear suitable anti-solvent gloves and use a gas mask.